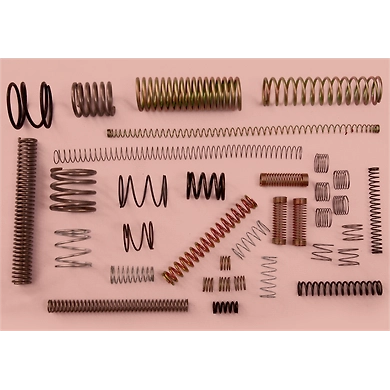

COMPRESSION SPRING

SKUWRC001

-

Product is not available

- Price upon request

-

-

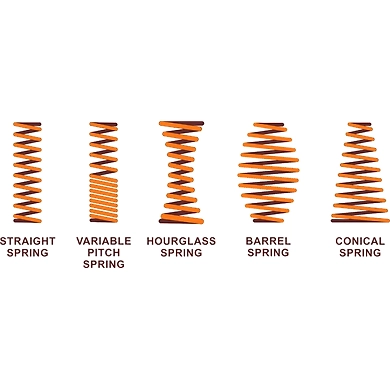

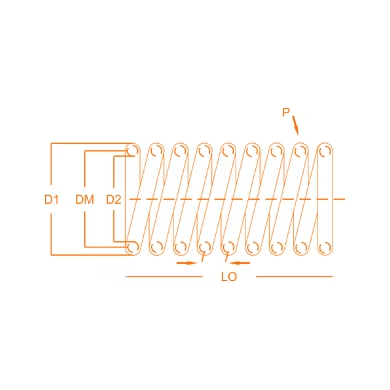

Compression Springs are designed to operate with a compressive load in “Push Mode”. Compression Spring also has variable pitch between coils which are used to reduce solid height, buckling and surging to produce nonlinear load deflection characteristics. Compression springs offer resistance to linear compressing forces and are in fact one of the most efficient energy storage devices available.

-

Additional Information

Material

Spring steel is considered a general use steel because of its ability to be durable, yet flexible with a high degree of strength. It has the unique ability to be formed, shaped, and post heat treated, which makes it one of the premium choices for manufacturing springs for automotive, auto electrical and electrical applications.

Stainless steel is good for corrosion resistant and Inconel is best for springs being used at very high temperatures.

When it comes to springs that are required to be non-magnetic, Stainless Steel 316 can be used. This material type isn’t 100% non-magnetic though. Stainless steel 316 is only 90% non-magnetic.

Finish

Compression Springs are available in Nickel, Yellow and White Zinc Plating, Black Oxidizing, Lacquering, Green Passivation and Trivalent Passivation.

Stainless Steel Springs are available with Bright Finish.

Manufacturing Process

Compression Springs are manufactured on imported CNC Spring Coiling Machines with SPC on line with free length sorting device for critical load value. -

Reviews ()

Write a Review